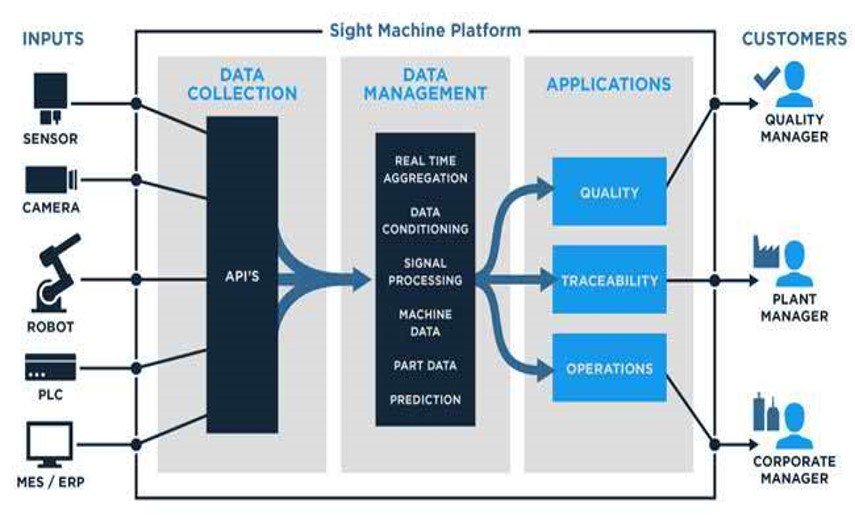

Sight Machine, a San Francisco based manufacturing analytics startup, is aiming to disrupt the manufacturing sector by providing an AI manufacturing analytics platform which acquires, refines, and contextualizes data to gain real-time visibility and actionable insights. Its FactoryTX platform gives manufacturers the flexibility to acquire machine data from both production facilities and the cloud. Its tools enable rapid deployment and centralized management of multi-factory IoT data ingestion. The insights are being generated in real-time and combine production data, equipment data, process quality data as well as installed ERP data and processed to generate valuable insights using AI and machine learning.

The key advantage of the platform is that not only it creates a digital twin of assets, but also of the process. With this platform, plant management can track material, man, and machine as well as the process, which drives continuous process improvement. Another advantage is that the platform can integrate data from machines of different manufacturers, ERP, historians and other sources to provide actionable insights and that too, across all manufacturing sectors. The main uses for the Sight Machine platform are quality improvement, predicting asset failure, predictive maintenance, reduce downtime, increasing capacity utilization, reducing scrap, increasing first-pass yield, measure and improve productivity and OEE (Overall Equipment Effectiveness).

Competition

Sight Machine competes with traditional ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) providers, which are expanding their portfolio by incorporating AI and machine learning to their ERP/MES platform to provide valuable manufacturing analytical insights. Major companies include SAP, Oracle, Netsuite, and Epicor. Other companies providing MES software include ABB, Siemens, Dassault Systemes, Rockwell Automation, etc.

However, Sight Machine claims that none of these companies are competitors, as its platform uses data from all these software to provide optimized manufacturing insights, which is its main advantage. The Sight Machine platform integrates data from these sources and other sensors and systems, aggregates the acquired data on its platform, applies ML and AI algorithms with its test-data, and generates insights to improve production, quality, equipment efficiency, and material flow.

Clients, Partners, and Investors

Sight Machine boasts Fortune 500 clients such as Heineken, Nissan, Westrock Co. and Asian Paints. Its platform can be used for both, continuous and discrete manufacturing industries. Sight Machine is optimized to run on the major cloud platforms including AWS, Google Cloud Platform, and Microsoft Azure. In addition, it has also partnered with system integrators (SI) like Fujitsu to support wide deployments. Sight Machine has raised about $60 million to date from leading venture capitalists such as GE Capital Ventures, E.ON, LS Group, etc. And recently announced an investment from the Sony Innovation Fund.

Sight Machine has made steady progress in the manufacturing analytics and digital twin space, acquiring funding from marquee investors. It has also secured good partnerships and clients. However, to drive further growth, it will need to expand its position in the biggest manufacturing hubs, i.e., China and Vietnam. The future looks bright, however, it needs to move fast by forming strategic partnerships, acquiring smaller players and entering into big manufacturing markets.